Project details:

This project builds a regression model that predicts the cost of producing industrial equipment. After cleaning the data and engineering meaningful features, several algorithms were evaluated. The final model helps the company estimate production expenses more accurately and plan budgets with greater confidence.

Description

Business Context & Problem

Manufacturers routinely face fluctuating production costs influenced by materials, equipment parameters and operational conditions. Inaccurate cost estimates can lead to budgeting errors and missed profit targets. This project focuses on predicting production costs using historical manufacturing data, giving the company a more reliable foundation for planning and pricing.

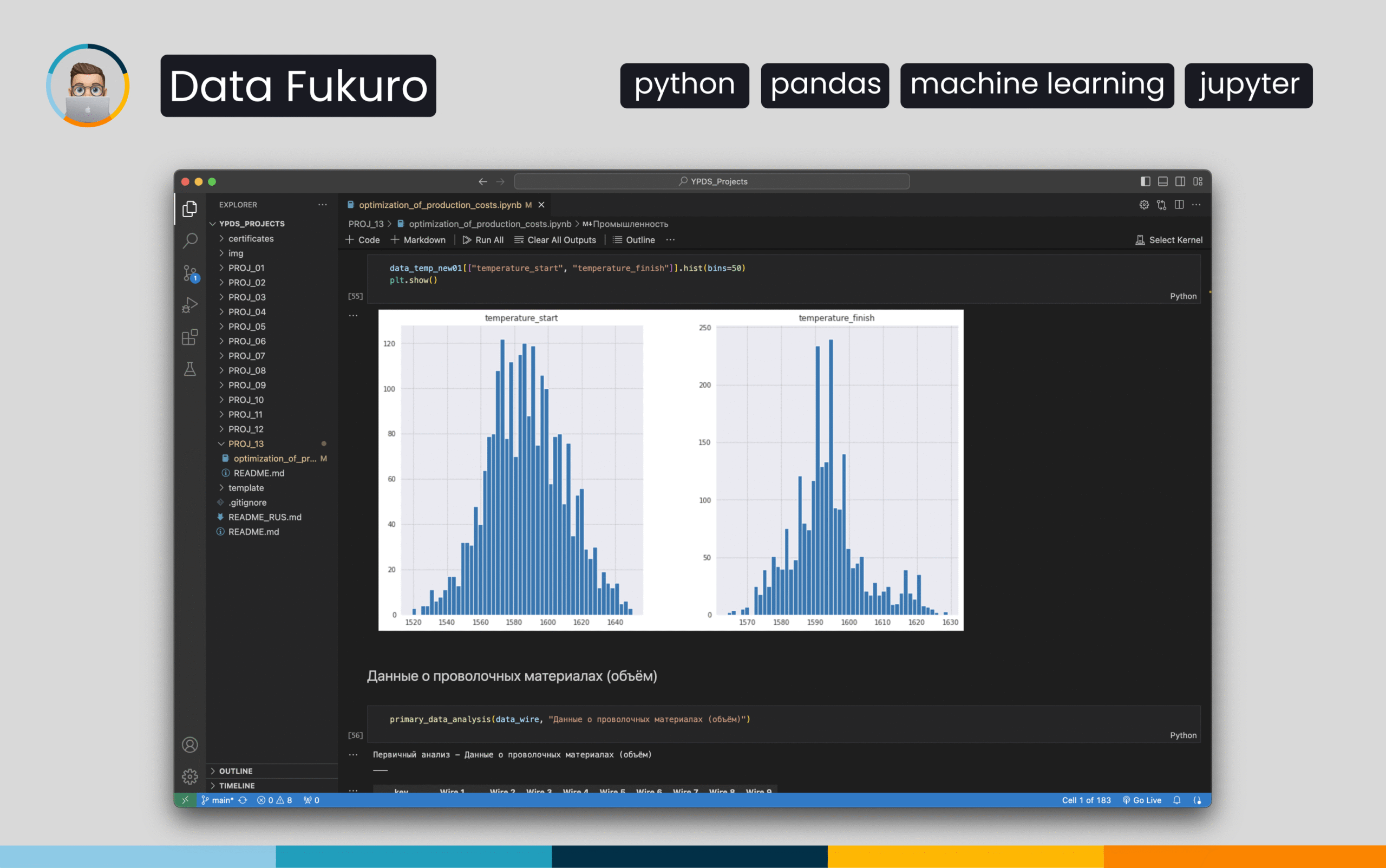

Data & Analytical Approach

The dataset included numerous technical parameters of industrial equipment and the corresponding production costs. Missing values were handled carefully, and outliers were checked to ensure model stability. Feature engineering introduced additional helpful variables, and categorical data was encoded for model compatibility. Exploratory analysis revealed which features had the strongest influence on cost.

Statistical / ML Analysis

Several regression models were tested, including linear models, tree-based methods and gradient boosting algorithms. Cross-validation was used to evaluate performance, and tuning improved the generalisation of the best models. CatBoost and LightGBM provided the strongest results thanks to their ability to handle non-linear patterns and mixed feature types efficiently.

Key Insights & Final Recommendations

The analysis identified core parameters that drive production cost, helping the company understand which factors should be monitored most closely. The final model offers accurate predictions that can be used to create more realistic budgets, optimise workflows and adjust pricing strategies.

Overall, the project provides a practical machine-learning approach for managing and forecasting manufacturing expenses.